產(chǎn)品展館PRODUCT CENTER

聯(lián)系我們CONTACT US

Add: #850 Yatai Road, Xiaoshan District, Hangzhou, China

Tel:+86-0575-87562186

+86 13906740412

Fax:+86-0575-87562186

E-mail:xsfld@vip.126.com

Web.:zygq.com.cn

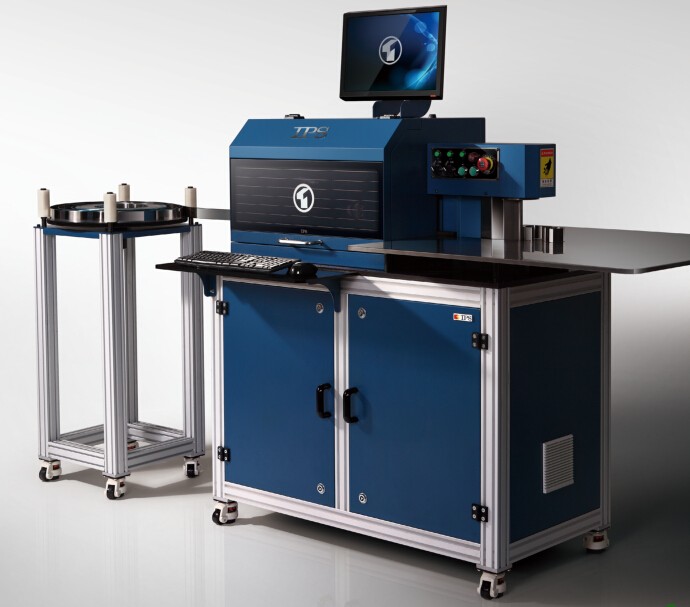

| Model No.:TPS-S8710 |

| Category:TPS Series Channel Letter Bending Machines |

TPS-S8710 Automatic Stainless Steel Sign bending machine is based on precise mechanical construction and a unique retractable alternating bending mode, use Pre-feeding leveling, clamping alternate feeding, and driving with wire rod double screw thumbs for slotting. Based on years of experience in the development of sign bending equipment developed by the TPS-AutoBend control system to ensure the letters processing precison, Especially fit for making letters with small radian, small angle and complex graphics. It is a high-end equipment for making LED signs, Steel letters, Piercing letters, and Epoxy letters.

Advantages of the equipment:

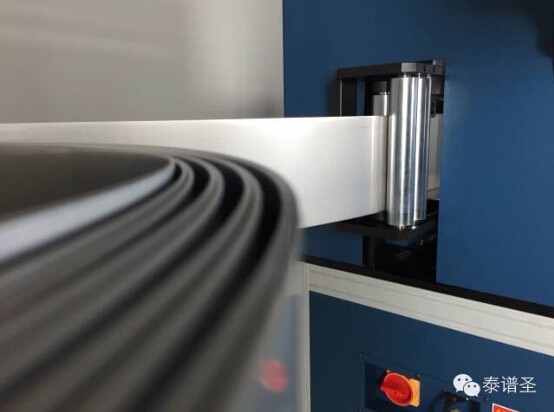

Straightening Mechanism

The machine is with a group of front setting material feeding leveling mechanism cooperating with the guiding channels to solve material stuck problem during feeding material and to ensure processing smoothly.

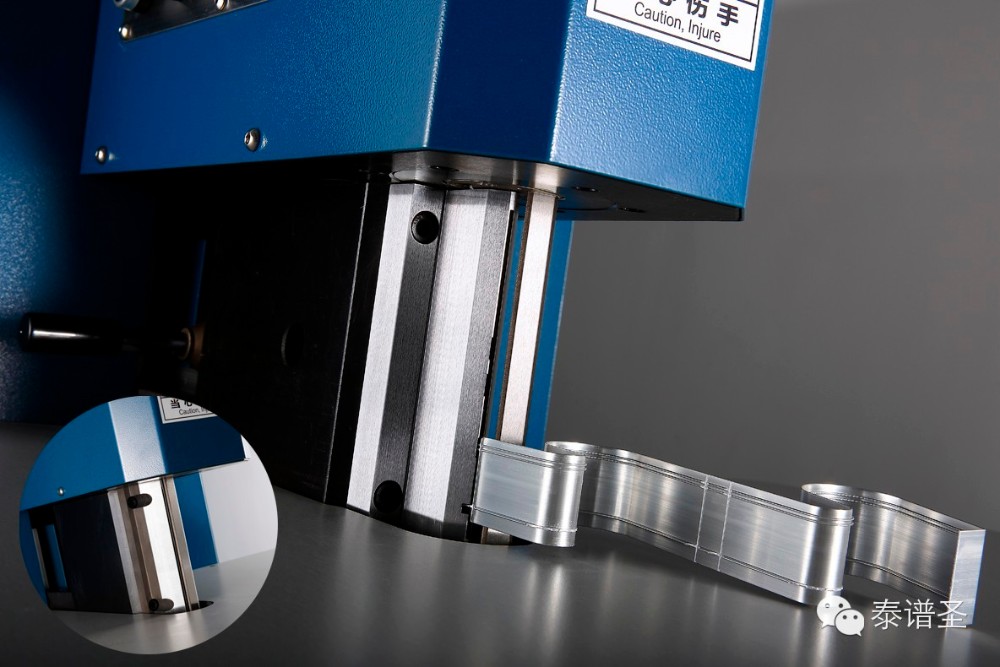

Alternating clamping feeding mechanism

The alternating clamping feeding mechanism with large torque, high precision and high speed transmission performance is driven with double screw rods and positioning nuts, and controlled by servo motor to ensure real material feeding accuracy to ±0.1mm. It solves problems of slipping and independent of roller pressure feeding type.

The function of punching for removing strip

The function of punching for removing strip of aluminum profile and V slotting type can completely solve problems of bad forming with traditional channel letter bending machine and small arc adjusted manually difficultly. It makes processing smoothly and quickly like bending for plain material. Using the blade for slotting the aluminum profile at positions of punch-removed strip.

And the blade cutting point can be grinded wider a little bit to avoid aluminum profile broken off easily during bending.

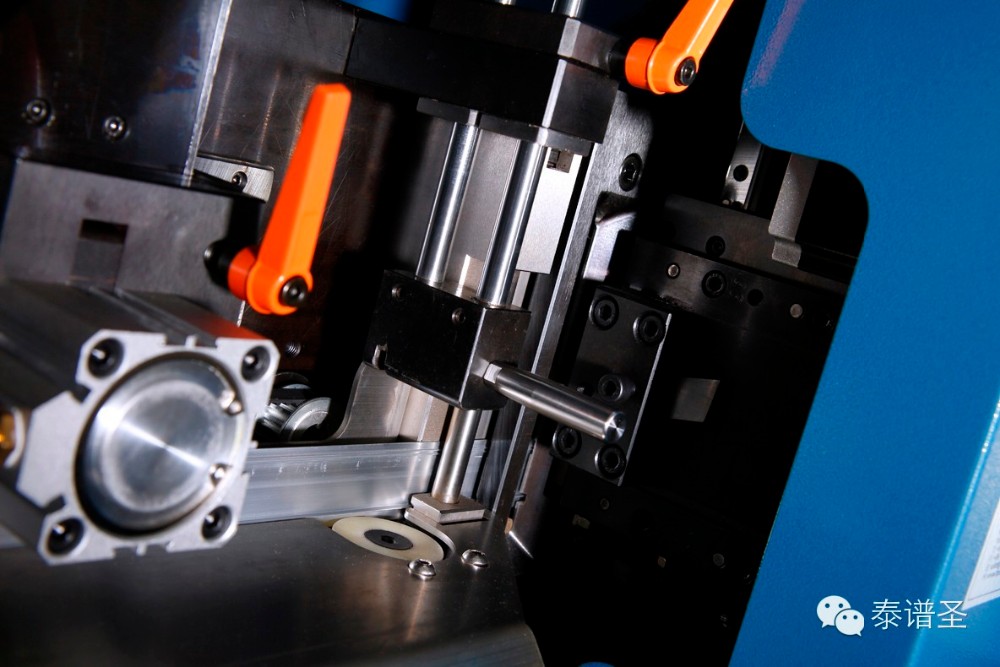

Bending tool quick-change system

In order to meet bending requirement for SUPER LETTERS with high quality and high accuracy, it uses the bending tool quick change system which can be changed quickly and independently between plain material and special aluminum profile for SUPPER LETTERS.

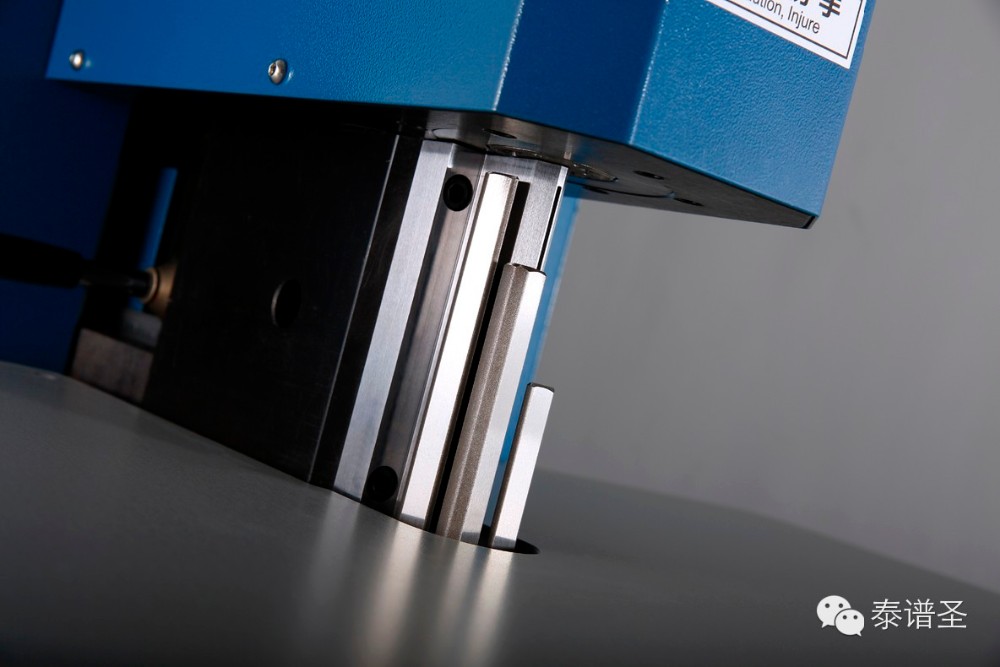

More tool rod bending system

On basis of the alternating double bending bars system, It is added a bending bar specially for aluminum profile making for SUPPER LETTERS that can realize processing for plain material and the aluminum profile in one machine. And it improves the bending forming without indentation almost on material surface.

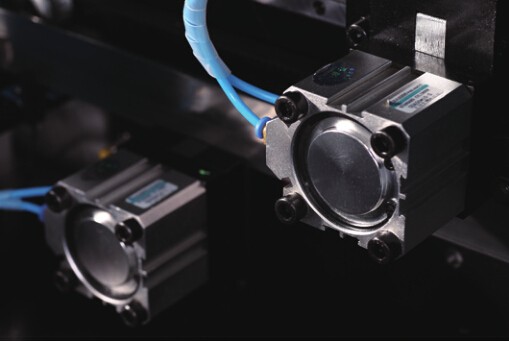

Closed-loop control

The encoder system can real-time monitor real material moving distance and bending micro-extension to realize closed-loop controlling for the graphics profile length and get fixing bended letters with face letters perfectly.

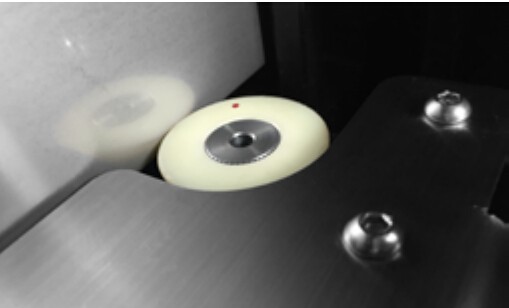

Slotting Mode

SlotDepth, SingleSlotDepth and SlotTimes can be set with our special software as users willing. Slotting mechanism is controlled by servo motor and driven by precision nuts with advantages of quick speed slotting, high precision and constant torque. Slotting lines are smooth without scratches and with same depth. It makes bending angles are sharp without arc to get bended letters clear and beautiful.

The function of punching for removing strip of aluminum profile and V slotting type can completely solve problems of bad forming with traditional channel letter bending machine and small arc adjusted manually difficultly. It makes processing smoothly and quickly like bending for plain material.

Software Advantages:

Built-in various surround types for making letters

Different surround type should be zoomed correspondingly for its graphic and calculate material wastage. Built-in various types for making letters realize making different types of bending letters without any complicated matching calculation to make processing easily.

The machine is including the software for counting cost of making SUPER LETTERS. The software can calculate the volume and the ratio of resin filling grease automatically and aluminum profile cost according to its graphic. It will be easier to check production cost and reduce waste.

Different property material and different material thickness make different springback. TPS controlling system of software can adjust bending power for different material easily and quickly during shifting material based on our further research. We just need to adjust a parameter of ArcCompensate on user parameters page for same property material with different width and different thickness. And parameters for corresponding material can be saved with data base. Users can select corresponding data for corresponding material to bend without complicated adjusting.

Technical Specification

| Power supply | AC200V |

| Power | 2.2.0KW |

| Compressed air | 0.4—0.8MPa |

| Control axis | 4pcs |

| Min. Bending radius | R7mm |

| Min. distance between interior angle and exterior angle | 4.5mm |

| Bending distance from start | 3mm |

| Applied material | Aluminium profile,Stainless steel,Galvanized sheet, Aluminium coil |

| Material thickness | Aluminum profiles:1.0mm Flat metal material:0.6-1.0mm |

| Processing height | Aluminum profiles:35/60/80mm Flat metal material:20-110mm |

| Material feeding method | Altermate feeding |

| Servo motor | 2PCS |

| Step motor | 2PCS |

| N.W. | 400Kg |